A global first in the industry! CCTV visits the Sany Shaoshan Lighthouse Factory

October 12,2024

Recently, the World Economic Forum officially released the latest list of "Lighthouse Factories". 22 manufacturing companies have joined the global lighthouse network, of which factories from China account for nearly 60%, setting a record high.

In the latest list of "Lighthouse Factories", Sany Heavy Energy's first super blade factory located in Shaoshan, Hunan, represents China's breakthrough from 0 to 1 in the wind power industry's "Lighthouse Factory". What disruptive innovations have been achieved here in the traditional wind power blade production model?

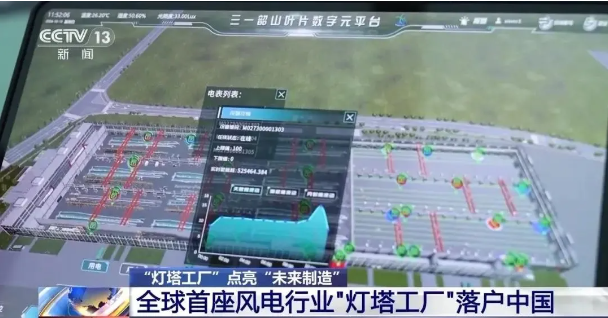

Entering this factory, the staff showed the reporter the real-time operation status and production data in the factory.

Peng Haibing, head of Sany Heavy Energy Shaoshan Blade Factory: On the flat panel, we can display the parameters of each unit, from temperature, humidity to torque, to the roughness of grinding, in real time, 360 degrees without blind spots, so that we can do real-time monitoring and lean management.

Peng Haibing, head of Sany Heavy Energy Shaoshan Blade Factory: On the flat panel, we can display the parameters of each unit, from temperature, humidity to torque, to the roughness of grinding, in real time, 360 degrees without blind spots, so that we can do real-time monitoring and lean management.

The staff told reporters that the blade, as the core component of the wind turbine, directly affects the power generation performance and reliability of the wind turbine throughout its life cycle, and its cost also accounts for 20% to 30% of the total cost of the unit.

The digital yuan platform, through digital and intelligent upgrades, gives the factory a "smart brain", ensuring the safety and reliability of the blade throughout its life cycle from the source.

The digital yuan platform, through digital and intelligent upgrades, gives the factory a "smart brain", ensuring the safety and reliability of the blade throughout its life cycle from the source.

Peng Haibing, head of Sany Heavy Energy Shaoshan Blade Factory: This industry-first technology has created a digital online factory from the overall outline to the detailed workstations of the factory of more than 80,000 square meters. This technology is also a benchmark technology in the wind turbine blade manufacturing industry.

The entire factory, through robots and laser guidance technology, has achieved unmanned processes such as automatic polishing of blade surfaces, large-area automatic painting, and automatic on-demand delivery of materials, reducing product defects by 20% and shortening delivery time by more than 30%.

The entire factory, through robots and laser guidance technology, has achieved unmanned processes such as automatic polishing of blade surfaces, large-area automatic painting, and automatic on-demand delivery of materials, reducing product defects by 20% and shortening delivery time by more than 30%.

These "firsts", "firsts", and "firsts" have shown us the continuous upgrading of China's manufacturing. I believe that in the future, more "lighthouse factories" will be born in China, not only lighting up the way forward for China's manufacturing industry, but also leading the development direction of the world's high-end manufacturing.

Source : www.51cm.com

Views : 4334

Tags : SANY