The world's first "lighthouse factory" in the wind power is built by Sany!

October 09,2024

On October 8, the world's first wind power industry lighthouse factory certification was established in Shaoshan Sany Heavy Energy Blade Factory in China, achieving a breakthrough from 0 to 1 in the wind power industry's lighthouse factory. Since then, China's wind power blade "smart manufacturing" has officially entered a new era.

The "lighthouse factory" is known as the "most advanced factory in the world". It was selected by the World Economic Forum (WEF) and McKinsey. It is a demonstrator of "digital manufacturing" and "globalization 4.0", representing the highest level of smart manufacturing and digitalization in the global manufacturing industry today.

Looking back at the development of wind power in my country, generations of wind power workers have worked hard, with awe of the power of nature, to accelerate China's wind power, bravely enter the "no man's land" of large-megawatt technology and the "deep waters" of digital transformation, and lead the global wind power transformation wave with the determination of "no destruction, no establishment".

Looking back at the development of wind power in my country, generations of wind power workers have worked hard, with awe of the power of nature, to accelerate China's wind power, bravely enter the "no man's land" of large-megawatt technology and the "deep waters" of digital transformation, and lead the global wind power transformation wave with the determination of "no destruction, no establishment".

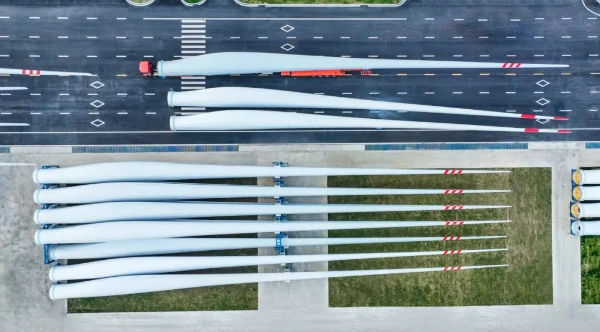

Blades, as the core components of wind turbines (referred to as wind turbines), directly affect the power generation performance and reliability of wind turbines throughout their life cycle. The cost of blades accounts for 20%-30% of the total cost of the unit. There is a consensus in the industry that "whoever gets the blades gets the world". However, the digitalization and intelligent upgrading of wind power blade manufacturing technology has always been a difficult problem that the industry cannot overcome, and wind turbine accidents caused by blades are endless.

Especially under the current trend of large-scale wind turbines, the length of blades has quickly exceeded 100 meters, and the subsequent changes in material selection and production process series have pushed the difficulty of transforming blades from "manufacturing" to "intelligent manufacturing" to a new height.

Flowers cannot bloom in poor soil, and high-quality blades cannot be produced with backward production processes and manufacturing lines.

Flowers cannot bloom in poor soil, and high-quality blades cannot be produced with backward production processes and manufacturing lines.

As a pioneer in China's wind power intelligent manufacturing and digital transformation, Sany Heavy Energy has built the industry's first super blade factory in Shaoshan, Hunan, based on its successful practice in the field of wind power mainframe intelligent manufacturing. It has subverted the traditional wind power blade production model and ensured the safety and reliability of the blade throughout its life cycle from the source.

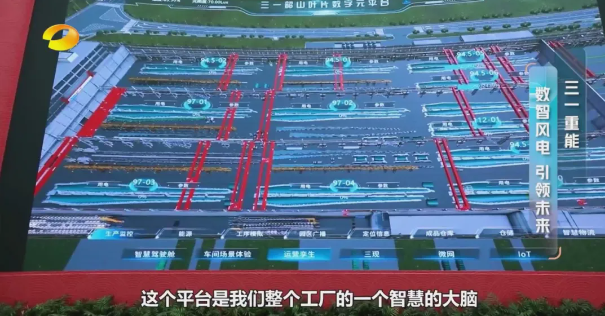

Super digitalization

Using the industry's first digital yuan platform to build the smart brain of the factory, an iPad can monitor all factory operations and production data in real time, from the temperature and humidity of the production unit to the process parameters and technical indicators such as bolt torque control and blade grinding flatness coefficient. Every key indicator that affects product quality will be presented on the platform, which is equivalent to building a "one-to-one" online digital factory outside the physical factory, so as to achieve 360-degree online monitoring and lean management of the entire production process.

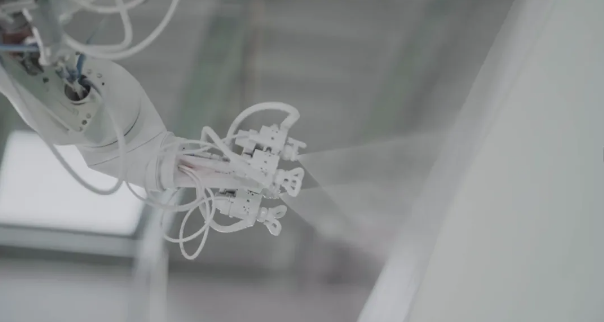

Super Automation

Super Automation

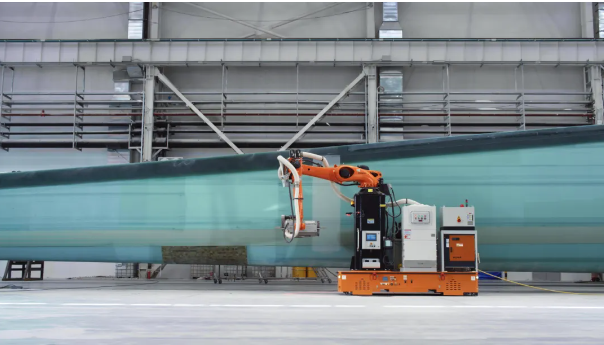

Ensuring product quality from the source is the original intention of Sany Heavy Energy to promote wind power intelligent manufacturing.

In the past, blade production was a labor-intensive industry, and people were the most important production factor and the biggest variable. During the production process, a large number of people were required to complete the processes of laying, pouring, grinding, painting, etc., which not only had low production efficiency, but also made it difficult to ensure quality consistency.

Sany Heavy Energy Shaoshan Blade Lighthouse Factory uses robots and laser guidance technology to realize unmanned processes such as automatic grinding of blade surfaces, large-area automatic painting, and automatic delivery of materials on demand, while reducing the labor intensity of employees and raising production efficiency and quality control to an unprecedented level.

Sany Heavy Energy Shaoshan Blade Lighthouse Factory uses robots and laser guidance technology to realize unmanned processes such as automatic grinding of blade surfaces, large-area automatic painting, and automatic delivery of materials on demand, while reducing the labor intensity of employees and raising production efficiency and quality control to an unprecedented level.

Taking blade infusion as an example, the Shaoshan Blade Factory uses the industry's first large-scale centralized infusion technology to achieve highly automated resin material input, storage, and use, making blade infusion as convenient and accurate as a car going to a gas station to refuel, and the infusion efficiency is increased by 25%.

As the world's first "lighthouse factory" in the wind power industry, Sany Heavy Energy Shaoshan Factory not only represents the Chinese wind power equipment manufacturing industry's entry into the world's first-class level, but also a successful practice of the transformation from "Made in China" to "Smart Manufacturing in China".

As the world's first "lighthouse factory" in the wind power industry, Sany Heavy Energy Shaoshan Factory not only represents the Chinese wind power equipment manufacturing industry's entry into the world's first-class level, but also a successful practice of the transformation from "Made in China" to "Smart Manufacturing in China".

Looking back on the past, Shaoshan, a red hot land, not only gave birth to the great revolutionary spirit, but also witnessed the great power of "Smart Manufacturing in China" in the new era of wind power. Today, Sany Heavy Energy Shaoshan Blade Factory stands proudly at the forefront of intelligent manufacturing like a lighthouse, becoming the focus of attention inside and outside the industry, and leading the world's wind power "smart manufacturing".

Source : www.51cm.com

Views : 4425

Tags : SANY